Oilfield tubing anchors come in a variety of sizes with an assortment of features. However, most anchors can be placed in one of two categories. The tools are either a tension anchor or a tubing anchor catcher. This article will explain the difference and highlight why the “catcher” feature can be so valuable.

What is a Tension Anchor?

Although there are exceptions, downhole tools like a quarter-turn anchor or a hydraulic tubing anchor can generally be classified as tension anchors. In both cases, when the anchor is fully set, it will hold the tubing securely, as long as the tubing is firmly attached to the wellhead. If the tubing breaks, parts or is disconnected, a tension anchor will not stop it from falling down the well. A tension anchor can withstand tens of thousands of pounds of upward pressure before it shears, but only a relatively small amount of downward pressure can send the anchor down the casing.

When Does a Tension Anchor Make Sense?

A tension anchor can be especially useful when the well design has to account for:

- Capillary tubing string. In wells where the perforations need additional stimulation or downhole-produced fluid chemistry creates scale, paraffin, iron sulfide, etc. and needs to be neutralized, capillary tubing string, or cap string, is an ideal solution to inject treating chemicals downhole. This small, stainless-steel tubing bands to the production tubing to follow it downhole and deliver the necessary chemicals. Using cap string with a mechanical tubing anchor catcher can be very difficult. The string must be “pre-wound” to account for the surface rotations required to set the anchor. Usually with a tension anchor no surface rotations are needed. The cap string can go straight down the well along with the production tubing.

- Extreme deviations. Some wells feature deviations that are so extreme it’s impossible to get surface rotation torque down to a tubing anchor catcher to fully set it. Once again, the tension anchor does not have the same limitation because no surface rotations are required.

What is the Catcher in a Tubing Anchor Catcher?

A tubing anchor catcher, or TAC, is different from a tension anchor in several important ways. Most notably, the TAC “locks” the tubing to the casing until it is mechanically released. Like a tension anchor, a TAC will hold the tubing securely to minimize unnecessary wear on downhole equipment as the tubing reciprocates with the release and onset of the hydrostatic load as the sucker-rod pump operates. Unlike a tension anchor, the TAC offers the same stability with downward pressure. Even if the tubing string is not connected to the wellhead, the TAC will hold it in place.

Production tubing can become damaged and part for several reasons. Sometimes corrosion is to blame. In other instances, the tubing collar is damaged or too much surface pressure splits the tube. In these instances, having a catcher in place is essential. By not allowing the entire tubing string to fall down the well, the TAC prevents a more extensive workover and/or fishing job, and it helps to avoid extended downtime.

What Other Benefits Does a TAC Provide?

In addition to the value of the catcher feature, a traditional mechanical tubing anchor catcher is especially useful for:

- Well repairs that don’t require replacing the anchor. Many well repairs do not require the replacement of the production tubing and anchor. If just a rod, valve or surface equipment need to be replaced, the entire production string may not need to be pulled. However, with a tension anchor, once the upward pressure is released, that anchor disengages. In contrast, a tubing anchor catcher would keep the production string in tension while the repairs are made.

- Well designs where cost is a key consideration. Depending on the model, a quarter-turn or hydraulic tension anchor can cost 2-3 times more than a comparable mechanical tubing anchor catcher. In some use cases, that higher cost is well worth it; but in others, it’s prohibitive.

- Wells where precise placement is critical. Setting a TAC in the optimal position requires precise tubing stretch calculations. A hydraulic tension anchor does not require a stretch calculation. While that simplicity is an advantage in some instances, it also means the placement of the anchor is somewhat subjective. A mechanical tubing anchor catcher allows engineers and rig crews to place the TAC in a precise location.

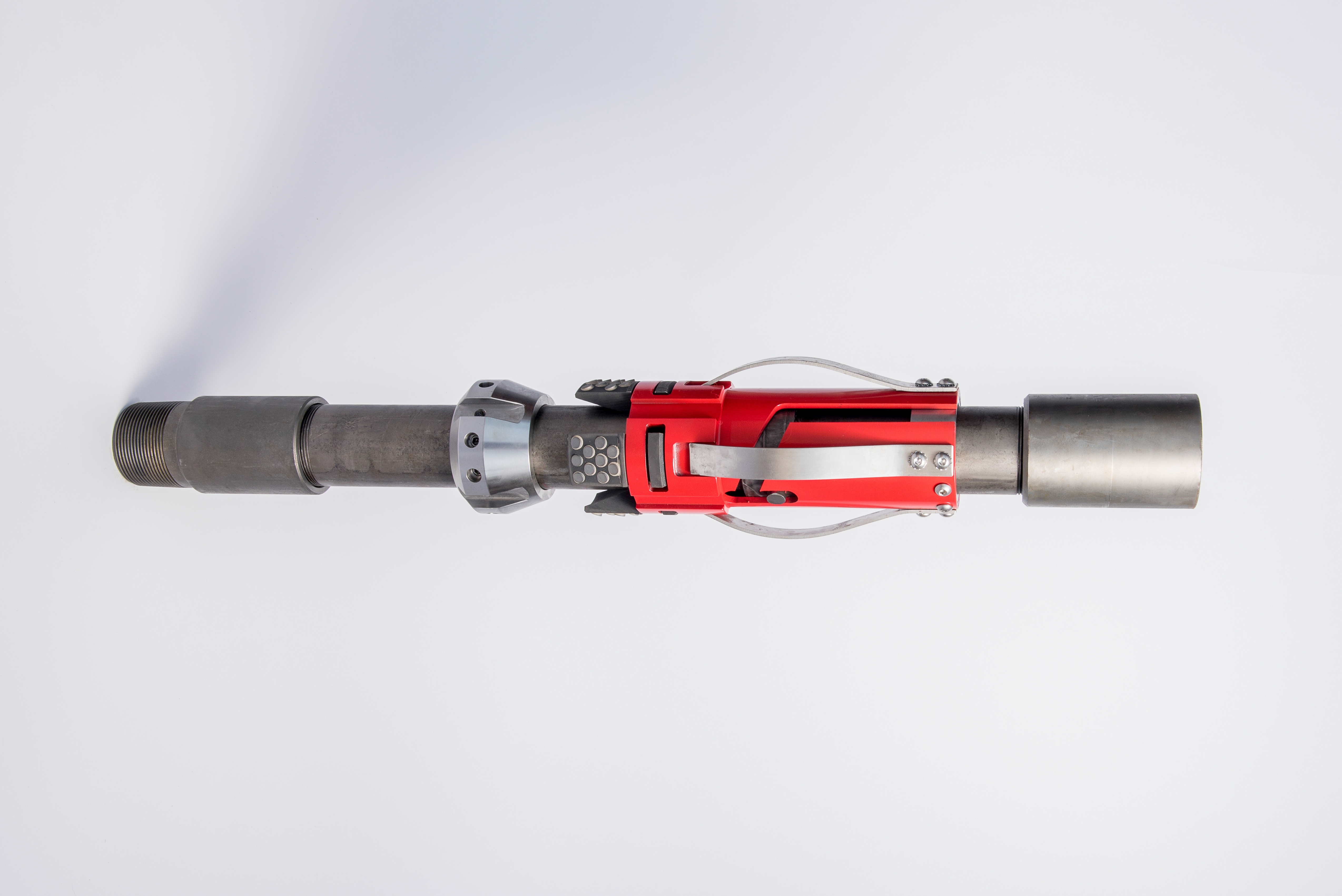

TechTAC® Offers Tubing Anchor Catchers and Tension Anchors

As the premier tubing anchor solution provider, TechTAC® offers many product options. From standard B2 TACs to quarter-turn tension anchors, we offer a range of solutions to accommodate most well designs. In addition, TechTAC® is also the home of the Slimline® Tubing Anchor Catcher and the Slimline® QuickSet™ TAC. Both models feature a reduced OD and a tapered design that allow for significantly more flow-by area compared to a standard B2 TAC. The Slimline® QuickSet™ has the added advantage of being able to be fully set in just 1-to-3 turns, making it an ideal solution for deep or deviated wells.

The unique design of the Slimline® allows gas to flow up and around the anchor while sand and sediment fall past it. That increased flow-by capacity helps to mitigate gas locking and reduce the number of stuck anchors.

To learn more or to get a quote on any of TechTAC’s tubing anchor catchers or tension anchors, contact the TechTAC® team today!