Recently we’ve had conversations with a handful of dealers and operators about how much torque to apply to our anchors. Specifically, how much torque should be applied to the TAC when attaching it to the tubing string. One operator even chastised our team for not making our torque specifications more accessible. It’s a fair criticism, so this article is a quick review of the TechTAC® Torque Chart and related instructions that can help crews avoid over torquing the subs on a TechTAC Tubing Anchor Catcher.

Understanding the TechTAC Torque Chart

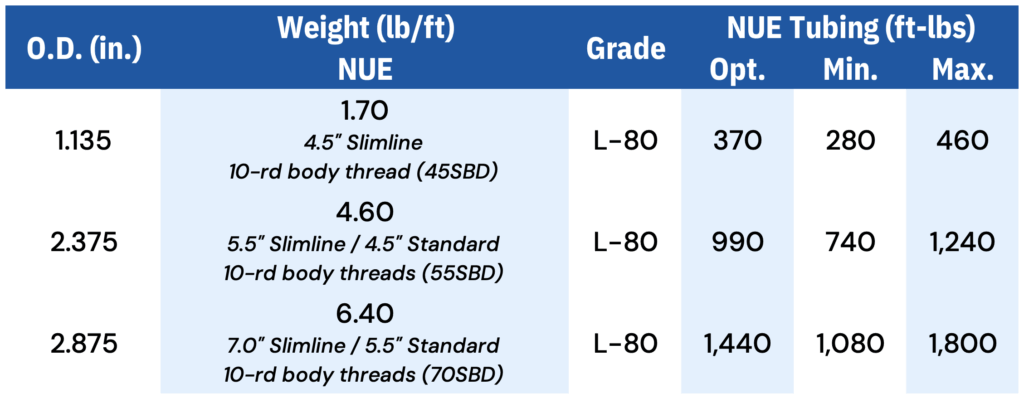

First, it’s important to understand the torque specifications associated with key parts of the tubing anchor. The male and female exterior ends of the subs on TechTAC anchors feature 8-round threads. This threading allows them to connect to conventional tubing. However, the connection between the anchor mandrels and the inside end of the subs is a 10-round thread. That means it has a different torque spec than the tubing. The TechTAC Torque Chart below highlights the minimum, maximum and optimal torque requirements for these 10-round connections.

Following Proper Setting and Releasing Procedures

However, understanding the torque specs is only half the battle. Following the steps outlined in TechTAC’s Setting and Releasing Instructions is also key. Here are a few excerpts from those instructions – and some additional commentary – that are particularly relevant to a discussion of torque:

- Do not tighten through the TAC when attaching it to the tubing string. When attaching tubing to the TAC, put a backup on the TAC subs. Doing so will help prevent over tightening and possible galling of the 10-round inner threads on the TAC. Sometimes in the interest of moving as quickly as possible, rig crews will attach the tubing to the top and bottom of the anchor and tighten the entire assembly without using a backup. Doing this risks significant damage to the anchor. It’s vital to attach the tubing to the bottom, set the backup and then tighten down the tubing. Doing so mitigates the risk of galling the interior threads. The same approach should be used when attaching the tubing to the top of the TAC.

- To prevent the TAC from setting while running in, it is recommended to occasionally (every 5-10 stands) use a pipe wrench to put a right-hand turn in the tubing (if running a right-hand set TAC, put a left-hand turn in the tubing).

- Whenever possible, set the TAC using pipe wrenches. However, if power tongs are needed, make sure the torque on the tongs is several hundred pounds less than what the tubing string was initially tightened with. This approach will help prevent the tubing from backing off.

Additional Resources

The complete library of setting, releasing and assembly instructions for TechTAC tubing anchors can be found at techtac.com/product-documentation. Being aware of the torque specs found in the TechTAC Torque Chart and carefully following documented procedures will help operators avoid some potentially costly downhole challenges. If you have additional questions on torque requirements or setting procedures, please contact a member of the TechTAC team by going to techtac.com/contact.