Article Summary

- Traditional B2-style tubing anchors have been linked to a myriad of downhole challenges in mature wells, including gas locking and scale formation.

- Resolving those challenges typically requires expensive workovers and days of downtime. For a field of 100 wells, those costs could exceed $600K annually.

- Many production companies have switched from standard B2 anchors to the Slimline TAC and experienced a dramatic reduction in the number of required workovers, a 25-30% increase in discharged gas, 15-25% increases in pump fillage, and up to 100% increases in daily production.

Traditional TACs and a Myriad of Downhole Challenges

Tubing anchor catchers, or TACs, are often an important part of the downhole production string. In wells using rod pump systems, they stabilize the string – and that stability prevents unnecessary cyclic movement of the tubing that can cause tubing failure and reduced rod pump efficiency and life. However, that same standard B2 anchor can create serious problems with well production and operating efficiency.

That was the finding of a research study conducted by Echometer Company. The Texas-based software firm offers solutions for analyzing and optimizing the performance of oil, gas and water wells. In this case, the firm studied the production rates of 11 oil wells. Each well had high fluid levels and the pump intake was located below the perforations. Yet despite these seemingly favorable conditions, nine of the wells showed a pump fillage rate of less than 90 percent.

Restricting Flow Through the Annulus

According to the Echometer report: “In these wells that exhibited high fluid levels … the fluid distribution in the wellbore below the liquid level was not uniform. The wellbore in the vicinity of the pump intake was primarily filled with gas with a minimal volume of liquid…. The presence of a tubing anchor set high above the pump intake is considered to be the main cause of this uneven distribution of fluids in the wellbore.

“The particular tubing anchor used in these wells provides a flow area of about 2.9 square inches between the body of the anchor and the casing compared to a flow area of 14.4 square inches between the casing (4.892-inch ID) and the tubing (2.375-inch OD). The small flow area could increase the velocity of the upwards flowing gas to the point where it would be difficult for liquid present in the upper part of the annulus to flow downwards past the depth where the tubing anchor is set. The anchor would essentially act as a choke and also cause an increase of the annular back pressure.”

In other words, the tubing anchor itself was restricting the flow of gas up through the annulus of the well. The gas that did escape had an increased velocity. That velocity made it difficult for fluid above the anchor to fall past it and reach the pump. In turn, the fluid around the pump had a high gas content, making highly efficient production impossible.

Providing a ‘False Positive’

Another key finding in the report was related to the fluid levels in these wells. In many cases, the fluid levels above the anchors appeared higher than they actually were. The report states: “Fluid level depression tests were used to confirm that free gas can collect below a tubing anchor and prevent the liquid present in the gaseous column above the tubing anchor from falling to the bottom of the wellbore and to the pump intake.”

Said differently, the fluid above the anchor was unable to fall past the anchor at a significant enough rate to allow full pump fillage and decrease the overall fluid level. This phenomenon essentially gave operators a false reading, since they thought they had high fluid levels. However, the reality was that fluid just couldn’t get past the anchor as quickly as it was being pumped out.

Noticeable Pressure Drop

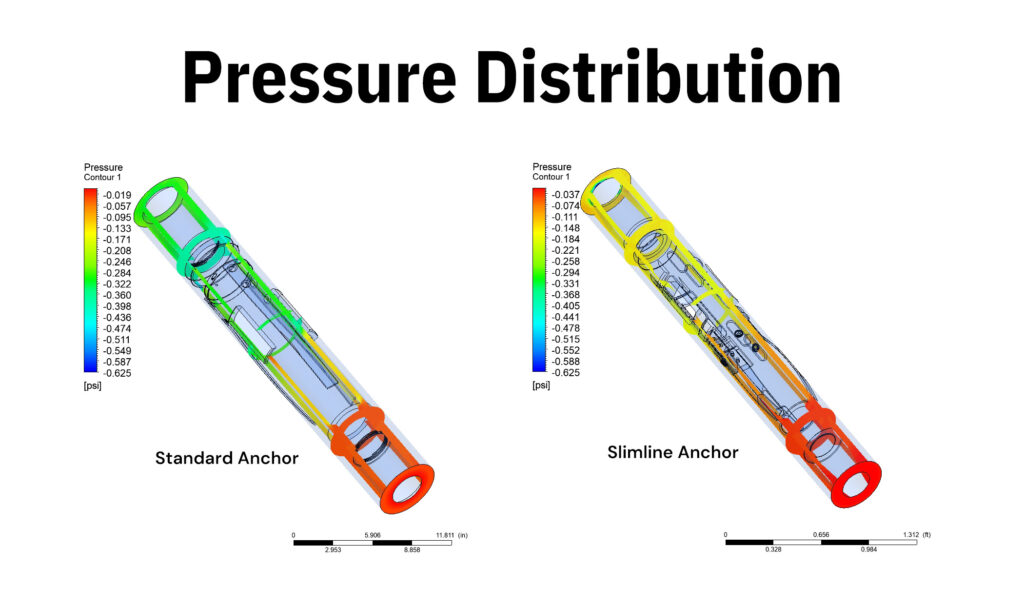

A separate study – a computational fluid dynamics (CFD) analysis by the independent consulting firm Imaginationeering – found that the small flow-by area around standard B2 TACs also contributes to a noticeable drop in pressure as fluid and gas move around the anchor.

The study, commissioned by TechTAC, provided “a comparison CFD analysis of a gas flow within the annular space around two types of a 5.5-inch tubing anchor catcher to assess the differences between them in terms of flow parameters.” According to the report, the pressure drop along the standard B2 anchor “is more than double the drop along the [comparison TAC]” and “a noticeable drop prior to the downstream connection is [also] observed.” A significant pressure drop, like that around the standard B2 anchor, is the primary issue causing gas locking in rod pumps and a major contributor in the formation of scale, iron sulfide and paraffin.

The Potential Financial Impact

One way to see the potential financial impact of the problems noted above is by modeling a scenario. The data and calculations below illustrate the annual costs that may be incurred across a field of 100 wells when standard B2 anchors are contributing to ongoing challenges with gas interference, scale and other issues. If you would prefer to modify the numbers used, visit TechTAC’s ROI Calculator.

The Scenario

The following parameters will be used for this sample scenario:

- Number of wells – 100

- Average number of barrels per day per well – 28

- Number of wells you have to pull prematurely each year because of a stuck anchor (e.g., scale, sand, etc.) – 4

- Number of wells that become gas locked each year – 20

- Price of crude per barrel – $72

Workover Costs

Whether changing out the rod pump or fishing a stuck anchor, workovers are typically required to remedy these production issues. For the purposes of this example, the following schedules and costs will be used:

- Average number of days for a complex workover to fish a stuck anchor and replace the rod pump – 5

- Average number of days for a workover rig to change out a sucker-rod pump (SRP) to minimize gas locking – 3

- Average cost per day for a complex workover to fish a stuck anchor – $7,500

- Average cost per day for a workover rig to change out an SRP – $5,700

Calculating the Impact

In this example above, four of 100 wells require a fishing job to retrieve a stuck anchor each year. Of those same 100 wells, 20 will become gas locked. The impact of the resulting downtime can be calculated based on both production losses and workover costs. The cumulative effect is a potential one-year financial impact of:

| Production losses due to downtime (bbls/yr) | 1,680* |

| Production losses due to downtime | $120,960 |

| Workover costs related to stuck anchors | $150,000 |

| Workover costs related to gas locking | $342,000 |

| TOTAL IMPACT | $612,960 |

*Production losses have been reduced by a factor of 0.75 to account for flush production.

One Simple Change in Mature Wells

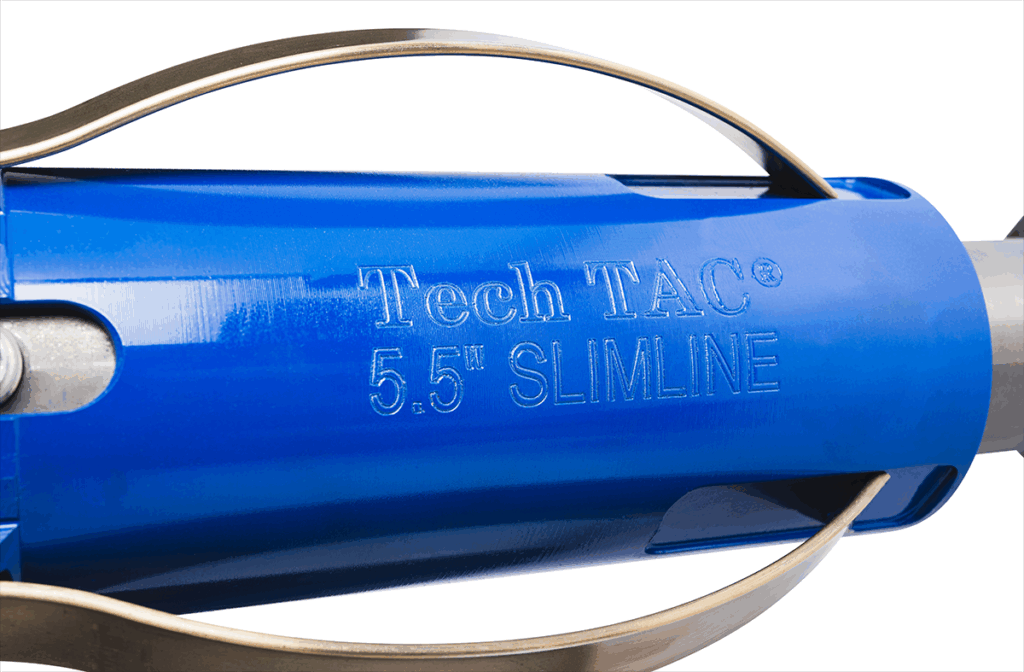

In an industry where well interventions can be so costly, one simple and relatively inexpensive change to the production string of mature wells can have an outsized impact on efficiency, production and cost containment. By replacing standard B2 anchors with the Slimline® TAC from TechTAC®, production companies can dramatically reduce the elevated operating expense and workover costs associated with gas interference, stuck anchors, and the formation of scale, paraffin and iron sulfide.

The design of the Slimline TAC – which includes a reduced OD and tapered flow deflectors – improves the flow-by capacity in the annulus by as much as 245% over a standard B2 anchor. That increased flow-by area allows gas to more easily flow up the well, rather than being trapped around the pump. It also allows sediment to drop past the anchor and mitigate the risk of plugging.

The previously mentioned CFD study found that the net pressure drop around a standard B2-style tubing anchor is more than double the pressure drop around the Slimline TAC. The Slimline anchor also demonstrated a noticeable advantage over the standard B2 TAC in reducing the overall turbulence and vorticity strengths within the flow field. In addition, the Slimline TAC exhibited “a more uniformly distributed velocity field.”

All those factors contribute to a tubing anchor that offers a far superior total cost of ownership and return on investment compared to a standard B2 TAC. Following are real-world examples of the benefits production and service companies have experienced switching from standard B2 tubing anchors to the Slimline TAC:

Reducing the Impact of Sand and Scale

“We have one well that had to be pulled every 3 months due to scale. After installing a Slimline TAC, we didn’t need to pull it for 2 years.”

>> Sr. Completion Foreman with a U.S.-based oil and gas company

“We were having problems getting standard anchors to both set and release due to sand and scale. With the increased annular area the Slimline provides, sand was able to fall past the anchor instead of accumulating on top of it. Both sand and scale bridging issues were dramatically reduced.”

>> Rig Operator with a large U.S.-based oil and gas company

“One of our production company customers had a well that needed to be pulled every 6 months; but since switching to a Slimline TAC that well hasn’t been pulled in the last 6 years.”

>> Owner of a downhole equipment supplier servicing the Eagle Ford Basin

Mitigating the Effects of Formation Gas

“[Slimline anchors] work well for gas interference issues in our wells with 5.5-inch casing. We’ve seen a 25- to 30-percent increase in the volume of gas being discharged on the surface.”

>> Production superintendent with an independent E&P company operating in the DJ Basin

“We had one well that had a 500,000 cubic feet of gas increase per day just by switching to a Slimline anchor.”

>> Sr. Completion Foreman with a U.S.-based oil and gas company

“The combination of the 5.5” Slimline TAC and a gas separator is a top-of-the-line solution for mitigating the issue of gas locking.”

>> Manager at a major distributor of artificial lift technology

Increasing Production

“We have seen increased pump fillage on wells we converted to the Slimline TAC. Increases of 15 to 25 percent are common.”

>> Production superintendent with an independent E&P company operating in the DJ Basin

“Wells do produce higher rates with a Slimline tubing anchor, so we want to run them where we can get them set without backing off tubing.”

>> Engineer with a large U.S.-based energy company

“All three wells [we switched to the Slimline TAC] went from producing roughly 40 barrels per day to approximately 80 barrels per day – a 100 percent increase.”

>> Production superintendent with an independent E&P company operating in the DJ Basin

Minimizing the Risk of Stuck Anchors

“We used to budget every year for 1 in 20 of the tubing anchors we ran to get stuck and need to be cut over. Since switching to the Slimline TAC, our number of stuck anchors has decreased dramatically.”

>> Engineer at a mid-sized production company operating in the Permian

“One of our oilfield customers ran four standard anchors down the same well, and each time the anchor would get stuck and then shear. When they finally tried a Slimline, the anchor set right away and has worked well ever since.”

>> Manager at an oilfield supply company in the Southern United States

“Sand was a frequent problem in many of our wells. It would fall on top of a standard TAC and cement the anchor in place. After switching to the Slimline, that problem all but disappeared.”

>> Engineer with a large production company operating in the Southern United States

Conclusion

With more than two decades of experience in the oil patch, the Slimline TAC continues to improve the efficiency and effectiveness of wells across North America and beyond. According to Bruce Friesen, a petroleum engineer and former global artificial lift advisor for BP, “[There are] multiple benefits of running the TechTAC Slimline anchor. Number one, reduce pressure and temperature drop, reduce turbidity and turbulence, which all four of those things contribute and cause the formation of scale, iron sulfide, paraffin and solids. [Eliminate] all those parameters … then you don’t have plugging. You don’t have stuck anchors. You don’t have workovers. You don’t have fishing jobs. And you also don’t have what is one of the biggest issues and problems and headaches in the oil patch is gas locking of your rod pump.”

To learn more about the Slimline TAC, including technical specifications, sizes and authorized dealers, download the Engineering Info Packet or Request a Quote.