How does the downhole performance of a traditional Baker Tubing Anchor Catcher compare with TechTAC’s Slimline® TAC?

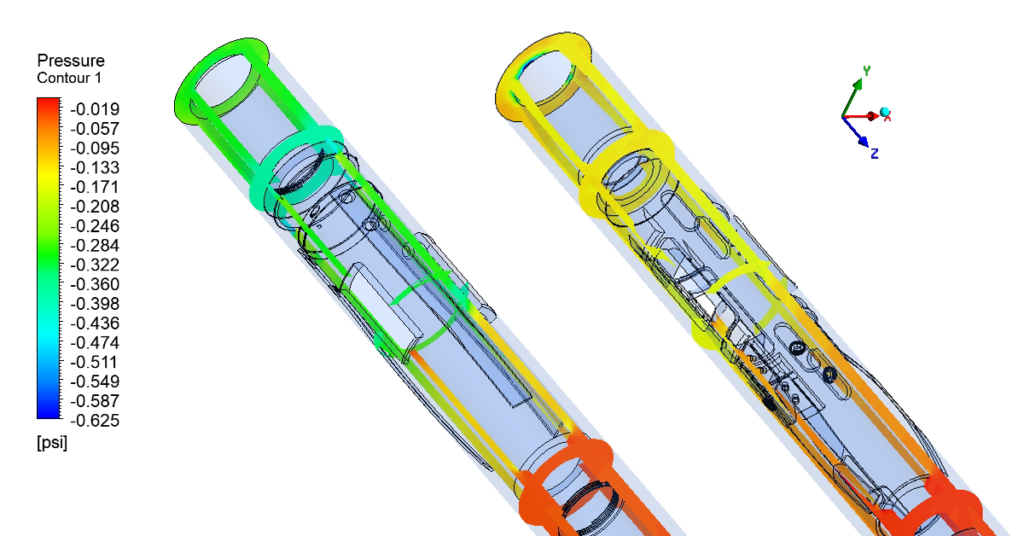

A new computational fluid dynamics (CFD) study poses that question. The study, commissioned by TechTAC® and conducted by the independent consulting firm Imaginationeering, provides “a comparison CFD analysis of a gas flow within the annular space around two types of a 5.5-inch tubing anchor catcher to assess the differences between them in terms of flow parameters.” Specifically, the analysis evaluated the performance of the tubing anchors relative to fluid velocity, pressure drop, turbulence, vorticity and other factors.

Key Finding: Significant Pressure Drop Around the Baker Tubing Anchor Catcher

One of the most significant findings of the CFD study dealt with the pressure drop around each anchor. The team at Imaginationeering found that the net pressure drop around a standard Baker Tubing Anchor Catcher, as fluid/gas passes through the annular cavity around the anchor, is more than double the pressure drop around the Slimline® TAC.

According to the study: “…the pressure drop along the Standard TAC is more than double that drop along the Slimline TAC. This is expected because the annular cavity with the Slimline TAC’s case is wider than that for the Standard TAC’s case. Furthermore, the pressure drop change in the Slimline TAC’s case is less abrupt than that in the Standard TAC’s case in which a noticeable localized drop prior to the downstream connector is observed.”

Key Finding: Less Turbulence and Vorticity Around the Slimline® TAC

The Slimline® tubing anchor also demonstrated a noticeable advantage over the Baker Tubing Anchor Catcher in reducing the overall turbulence and vorticity strengths within the flow field.

The report noted, “The observed abrupt changes in the pressure field along with the potential presence of flow field obstacles in the case of the Standard TAC is expected to generate more turbulence within the flow field along the TAC in comparison with the Slimline TAC’s case… Further, the vorticity strength in the flow field of the Standard TAC is expected to be significantly present in comparison to that of the Slimline TAC’s case….”

The Impact of the CFD Study Findings

The significant pressure drop and increased turbulence and vorticity as fluid passes around the Baker Tubing Anchor Catcher can have a material impact on well production. Those parameters are major contributors in the formation of scale, iron sulfide and paraffin, and they play a role in the advent of gas locking.

“[The CFD study highlights] multiple benefits of running the TechTAC Slimline anchor,” said Bruce Friesen, former global artificial lift advisor for BP. “Number one, reduce pressure and temperature drop, reduce turbidity and turbulence, which all four of those things contribute and cause the formation of scale, iron sulfide, paraffin and solids. [Eliminate] all those parameters … then you don’t have plugging. You don’t have stuck anchors. You don’t have workovers. You don’t have fishing jobs. And you also don’t have what is one of the biggest issues and problems and headaches in the oil patch is gas locking of your rod pump.”

Get a Free Copy of the CFD Study

To receive a summary of the CFD study comparing a Baker Tubing Anchor Catcher with the Slimline® TAC, visit the report download page. You can also watch a video of Bruce Friesen breaking down the study’s results from an engineering perspective.