In the world of oil and gas extraction, the stability and efficiency of downhole equipment are crucial to the success of any operation. One of the key components ensuring this stability in wells using sucker-rod pumps for artificial lift is the tubing anchor. Whether it’s to maintain tubing alignment or prevent tubing movement, tubing anchors play a critical role in maintaining well integrity and enhancing production.

In this comprehensive guide, we will explore the different varieties of oil well tubing anchors, their applications, benefits, and limitations.

What is a Tubing Anchor?

A tubing anchor is a downhole device installed in the tubing string of an oil/gas well to anchor the tubing in place within the casing. Its primary purpose is to eliminate or control the axial movement of tubing caused by temperature changes, pump action, or pressure fluctuations. Properly selected and installed tubing anchors enhance artificial lift efficiency, reduce wear and tear on equipment, and prevent tubing failure.

There are several types of tubing anchors available, each with distinct advantages and limitations. The main varieties used with sucker-rod pumps include:

- Mechanical Tubing Anchor Catchers

- Quick-Setting Tubing Anchor Catchers

- Quarter-Turn Tension Anchors

- Hydraulic Anchors

Let’s dive into each of these types in detail.

1. Mechanical Tubing Anchor Catchers

Overview:

Tubing anchor catchers (TACs) are mechanical-set anchors that grip the casing and lock the tubing in place. These are typically run with rod-pumped wells and serve a dual function: anchoring the tubing and catching it in case of separation.

Advantages:

- Dual functionality: They act as both an anchor and a safety catcher.

- Simple design: Relatively easy to install and retrieve.

- Cost-effective: Often more economical than more complex anchor systems.

Limitations:

- Mechanical wear: Potential difficulties when releasing in high-debris environments.

- Manual setting: Requires specific downhole conditions and procedures for proper setting.

- Limited for high-deviation wells: Performance may degrade in highly deviated or horizontal wells.

Best for: High or low productivity conventional vertical wells.

2. Quick-Setting Tubing Anchor Catchers

Overview:

Quick-setting tubing anchor catchers are nearly identical to traditional mechanical TACs, except that they can be fully set and released in as little as 1-to-3 turns, as opposed to the usual 6-to-8 turns. This feature gives quick-setting TACs broader applicability in deviated wells.

Advantages:

- Dual functionality: They act as both an anchor and a safety catcher.

- Streamlined setting procedure: Setting and releasing the anchor requires fewer surface rotations.

- Versatility: Can be deployed in wells with more extreme wellbore geometry.

- Cost-effective: Often more economical than more complex anchor systems.

- Extraction: Easier to release in a high-debris environment.

Limitations:

- Manual setting: Requires specific downhole conditions and procedures for proper setting.

- Smaller margin of error: Not following prescribed setting procedures can cause the anchor to set or release prematurely.

- Learning curve: The relative newness of quick-setting TACs could warrant training for some rig crews.

Best for: Deep wells, in the curve of a horizontal well, or where the deviation survey indicates high dogleg severity or cork-screwed wellbore geometry.

3. Quarter-Turn Tension Anchors

Overview:

Quarter-turn tension anchors are designed to hold the tubing in tension, rather than lock it in place. Like TACs, tension anchors are set mechanically, but the most common variations leverage an auto-J release mechanism that requires only a one-quarter rotation to engage.

Advantages:

- Mitigates tubing stretch: Prevents unwanted tubing contraction or extension.

- Simple setting mechanism: Sets with minimal surface rotations and without the use of threading.

- Supports deviated wells: Often run in deep or deviated wells where it’s difficult or impossible to fully set a traditional anchor.

Limitations:

- Higher cost: Typically more expensive than traditional mechanical anchors.

- No “catcher” capability in some models: Without this, the anchor will not stop parted pipe from falling into the well.

Best for: Deep or deviated wells where a traditional mechanical anchor cannot be fully set.

4. Hydraulic Anchors

Overview:

Hydraulic tubing anchors use tubing pressure to activate the anchoring mechanism. These anchors are ideal for deep wells or highly deviated wells where mechanical setting is difficult.

Advantages:

- Pressure-activated: No need for surface manipulation or tubing movement to set.

- Ideal for horizontal/deviated wells: Effective in non-vertical geometries.

- Solution for capillary string: Can be effectively used in wells that rely on capillary string to deliver stimulating chemicals.

Limitations:

- Higher cost: Typically more expensive than mechanical anchors.

- No “catcher” capability in some models: Without this, the anchor will not stop parted pipe from falling into the well.

- Dependence on induced tubing pressure: Requires adequate hydraulic force to activate and maintain tension.

- Lack of precision: Placement of the anchor requires good pipe tally.

Best for: Deep or deviated wells with high-pressure environments and limited mechanical access.

Choosing the Right Tubing Anchor

Tubing anchors are indispensable in ensuring the integrity and efficiency of oil well operations. Selecting the ideal tubing anchor for your well depends on several factors:

- Well depth and geometry (vertical vs. horizontal)

- Artificial lift system used (rod pump, PCP, etc.)

- Expected tubing movement (thermal, mechanical)

- Wellbore pressure and temperature

- Cost and maintenance considerations

In addition, a strong understanding of the different types of tubing anchors—including mechanical tubing anchor catchers, quick-setting TACs, quarter-turn tension anchors, and hydraulic anchors—can help operators make informed decisions tailored to specific well conditions.

While each type offers unique advantages, they also come with limitations that must be weighed during the planning and installation phases. Whether you’re managing a shallow vertical well or a complex horizontal operation, the right tubing anchor can significantly enhance the safety, reliability, and productivity of your oilfield operations.

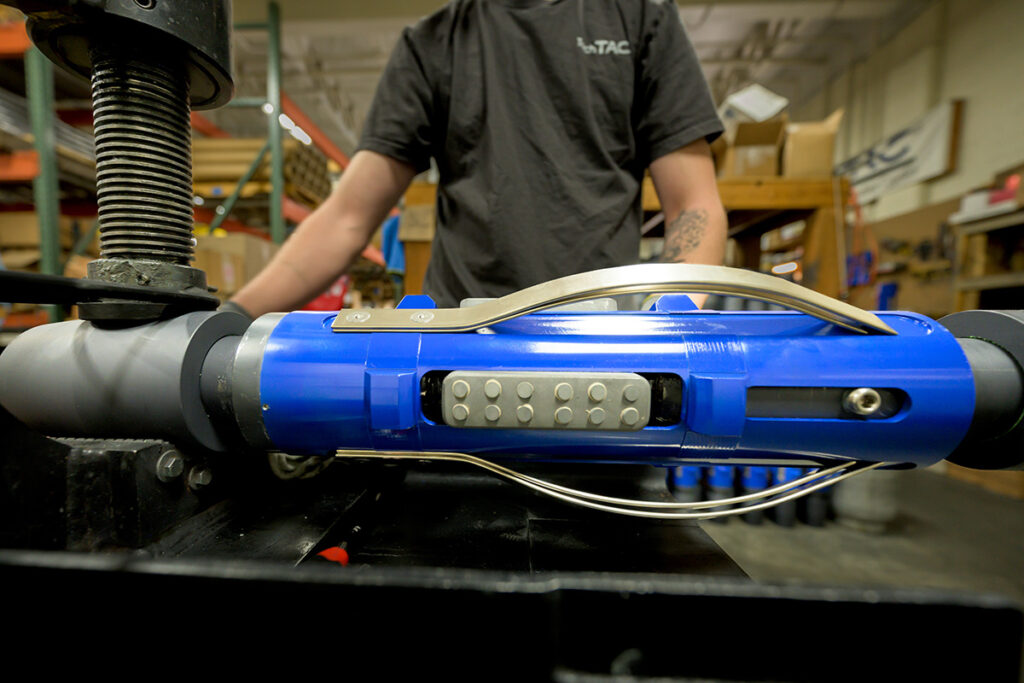

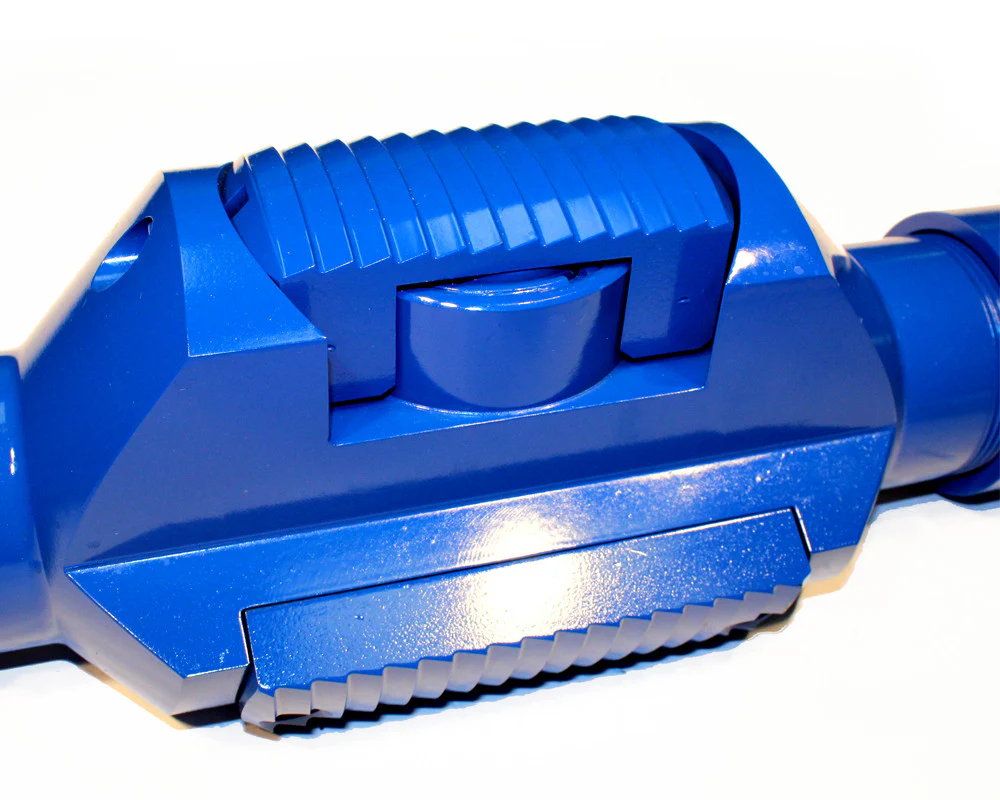

Consider the Slimline Tubing Anchor Catcher from TechTAC

The tubing anchor catcher is the most common downhole anchor in wells using rod pumps for artificial lift. It has been a staple of the oil industry for decades, minimizing wear on rods, tubing, casing, and the rod pump; preventing the tubing from contracting and stretching; and stopping any parted pipe from falling into the well. However, traditional B2-style anchors can also make a well susceptible to several common problems. Because the annular area between the standard B2 TAC OD and the casing ID is so small, the anchor can create a choke point that can reduce the ability of gas to breakout and migrate to the surface, which in turn reduces pump fillage and can gas lock the pump. This restriction also creates a pressure drop at the anchor, producing an environment conducive to the formation of scale, iron sulfide, and paraffin.

An alternative to the standard B2 TAC, which has the potential to significantly improve well productivity and lower lifting costs, is the Slimline® Tubing Anchor Catcher from TechTAC®.

Greater Efficiency with the Slimline TAC

The reduced OD and unique design of the Slimline TAC allows for up to 245% more flow-by area between the anchor and the casing. In some well designs, that increased annular area can not only significantly reduce gas interference and scale, but it can also boost production and lower lifting costs by:

Increasing pump fillage

Many operators have experienced a boost in production after replacing standard B2 anchors with the Slimline TAC. One such customer – a superintendent with an independent production company – said, “We have seen increased pump fillage on wells we converted to the Slimline TAC. Increases of 15-to-25 percent are common.

“The typical wells we have installed the Slimline anchors in are horizontal wells with an average total fluid rate of 20-to-25 bbls per day. We have increased the majority of these to 35-to-40 bbls per day due to increased pump fillage and runtimes.”

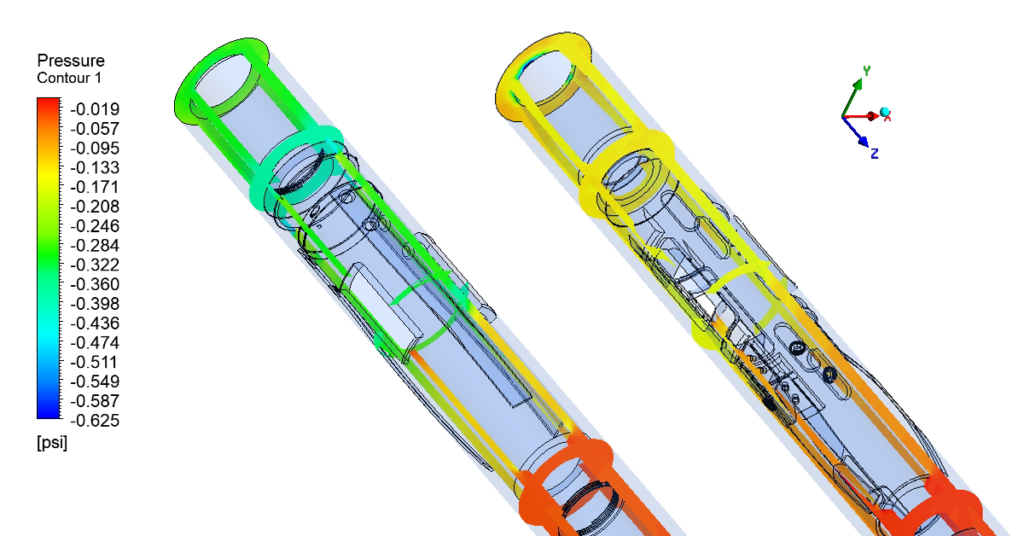

Minimizing pressure drop

According to CFD research, the net pressure drop around a standard B2 anchor, as fluid passes through the annular cavity around the anchor, is more than double the pressure drop around the Slimline TAC. That pressure drop is not only a primary contributor to gas interference and scale formation, but it also creates a more turbulent fluid flow – all of which have a negative impact on production.

In contrast, the design of the Slimline TAC creates far less pressure drop and therefore greater production. Speaking to these advantages, one engineer with a Fortune 500 energy company said, “Wells do produce higher rates with a Slimline tubing anchor, so we want to run them where[ver] we can get them set….”

It should also be noted that the production benefits of the Slimline TAC don’t just apply to oil-only wells. Gassy oil wells can benefit significantly as well. A senior completion foreman with a subsidiary of an oil major explained, “We had one well that had a 500 mcf gas increase per day just by switching to a Slimline anchor.”

Could the Slimline TAC Benefit Your Designs?

TechTAC offers a wide variety of technical and business resources to help engineers and operators determine if the Slimline TAC could increase their oil well efficiency. Some of those resources include:

- A library of technical and product documentation

- A downloadable Engineering Info Pack that includes CFD study results, setting procedures, customer references and more

- An ROI Calculator to model the financial impact of switching from a standard B2 anchor to the Slimline TAC

- A blog filled with best practices and customer use cases

For more specific questions or to get a quote, you can contact a member of the TechTAC team by visiting techtac.com/contact.