Ready to talk with a team member?

We have product and industry experts standing by.

Check out some of the most common Q's and A's related to TechTAC® and the Slimline® Tubing Anchor Catcher.

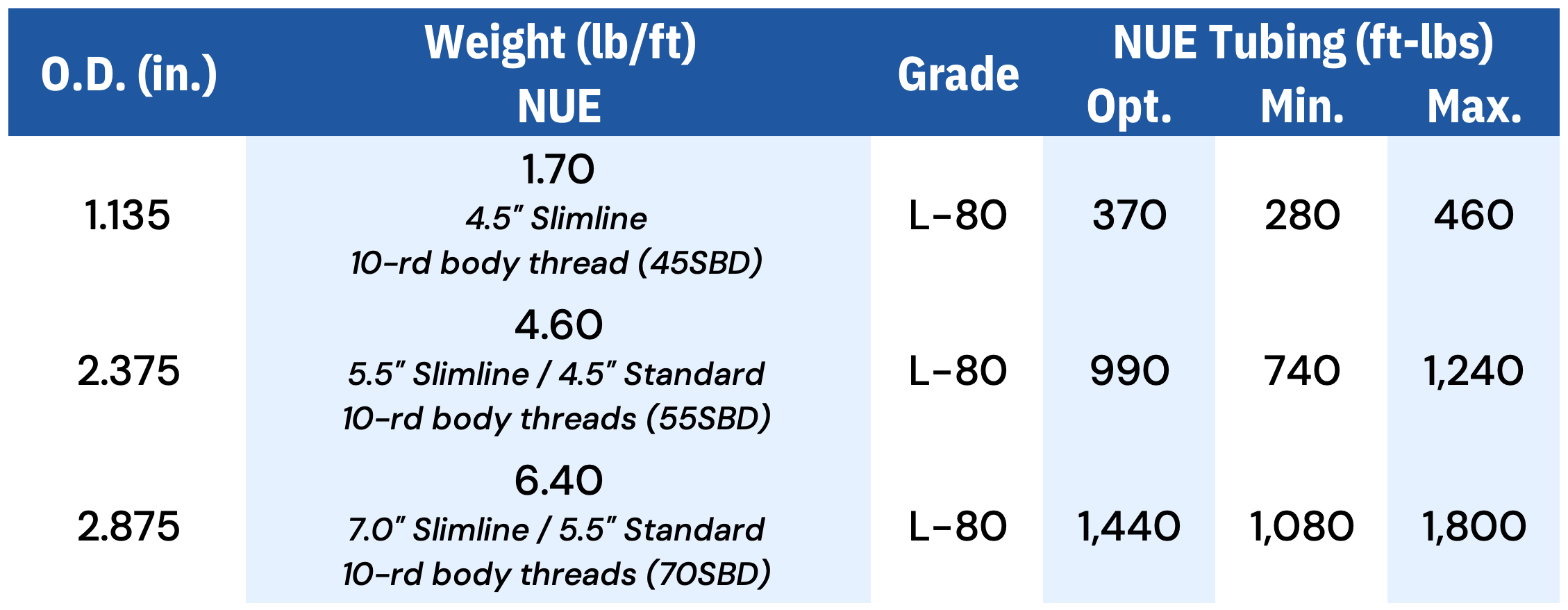

The male and female exterior ends of the subs on TechTAC tubing anchors feature 8-round threads to connect to conventional tubing. These threads typically match the torque specifications of the well tubing. However, the connection between the anchor mandrels and the inside end of the subs is a 10-round thread. That means it has a different torque spec than the tubing. Follow the guidelines in this post and the specifications in the TechTAC Torque Chart below to help crews avoid over torquing and possibly galling those interior threads.

Yes. Due to the increased annular area provided by our Slimline® Tubing Anchor Catchers, we are able to customize our tools to operate in several unique downhole conditions, such as setting in a liner or below a casing patch. We modify the tools to the exact, well-specific dimensions needed in order to provide an effective tubing anchor catcher solution.

TechTAC offers a number of options for TAC placement. For example, the 5.5" Slimline TAC can be set above or below the seat nipple in a well using 2-3/8" tubing. Traditionally, setting the anchor below the pump has not been ideal, but with the reduced OD of the Slimline TAC, the risk of material building up on top of the anchor has been greatly reduced or eliminated. If, on the other hand, a 5.5" well is using 2-7/8" tubing, the original Slimline TAC can be set below the pump; or, the Slimline® Full Bore™ TAC can be set above the seat nipple with a large pump running through it. Contact the TechTAC team to discuss your specific well requirements.

Absolutely. As with any downhole tool, in worst-case scenarios it may be necessary to cut over a Slimline anchor. A conventional tubing anchor catcher can take several days to cut over, because the conventional anchor’s OD requires that the entire length of the tool must be milled to be removed. In contrast, our TechTAC Slimline Tubing Anchor Catchers can dramatically reduce that cut over time because only the slip protectors and slips need to be cut. The rest of the tool fits inside a mill shoe or washover pipe. We have testimonials of our anchors being cut over in as little as 20 minutes. This benefit alone allows you to set the tubing anchor catcher deeper in the well with less worry about retrieving it.

If it is impossible to release the Slimline Tubing Anchor Catcher in the designated manner, all tools are equipped with emergency shear pins. An up-strain greater than the total shear strength of the shear pins plus the weight of the tubing will shear the pins and release the tubing anchor catcher.

TechTAC sells through local pump shops and service companies and will happily contact the service company of your choice. This allows operators to continue using the service companies they know and trust while expanding the inventory of the service company. Contact us today to find or add an authorized dealer near you!

The Slimline anchor can be set above, in or below the perforations, depending on the size of the sucker-rod pump installed. With the decreased overall diameter and tapered flow deflectors, our tools can greatly reduce the tubing anchor restriction in the annulus.

You will still get the safe, reliable setting procedure of a conventional tubing anchor catcher, only now you have less restriction, better flow-by, and more options on where to set the tool. With such a small area between the tool and casing, a standard B2 tubing anchor catcher can act as a choke, restricting gas flow up the annulus or gathering sediment on top of the anchor that can harden over time. With our patented Slimline TAC design, flow-by capacity up the annulus has been shown to increase by as much as 245% when compared to a standard anchor. This increased capacity allows for fluids to more easily fall past the tool, allowing gas to break out easier and reduce the risk of a stuck string. In addition, the Slimline® QuickSet™ TAC only needs 1-to-3 counter-clockwise turns to set the tool versus 6 to 8, thereby allowing for a much more reliable set in deviated wells.

Yes. The smaller outside diameter of the patented Slimline Tubing Anchor Catcher increases flow-by capacity and reduces the overall restriction, or “choke,” provided by a standard tubing anchor catcher. This design allows natural gas to break out easier up the annulus and not be forced through the pump, thereby greatly reducing the occurrence of gas locking.

We currently offer 4.5″, 5.0″, 5.5″, 6.0", 7.0″, and 7-5/8″ Slimline Tubing Anchor Catchers, with other sizes available upon request, including unique or custom-built tools.

Our Slimline Tubing Anchor Catchers set and release the same as most standard B2 tubing anchor catchers: left-hand set, right-hand release. Complete instructions are provided on our Product Documentation page.

Our tools utilize emergency shear pins which provide 5,000 lbs of shear per pin. The max shear allowed on our 4.5” Slimline TAC is 50,000 lbs. On the 5.5” and 7.0”, it is 60,000 lbs.

Yes. Typically tools are left-hand set but right-hand set tools are available upon request.

Watch this brief video to see an overview of the benefits of the Slimline TAC compared to a standard B2 anchor.

In deviated and cork-screwed wells, it’s difficult to get the torque from surface turns down to the anchor, especially in deeper wells. The Slimline QuickSet TAC, however, only requires 1-to-3 turns to fully set versus 6 to 8, thereby reducing the required torque that builds up in the tubing string.

The Slimline TAC’s increased flow-by area compared to a standard B2 anchor provides for less velocity around the anchor, thus resulting in less pressure drop. Scale and other plugging agents tend to form at areas where there is a pressure drop.

We have product and industry experts standing by.