Slimline® Full Bore™ TAC

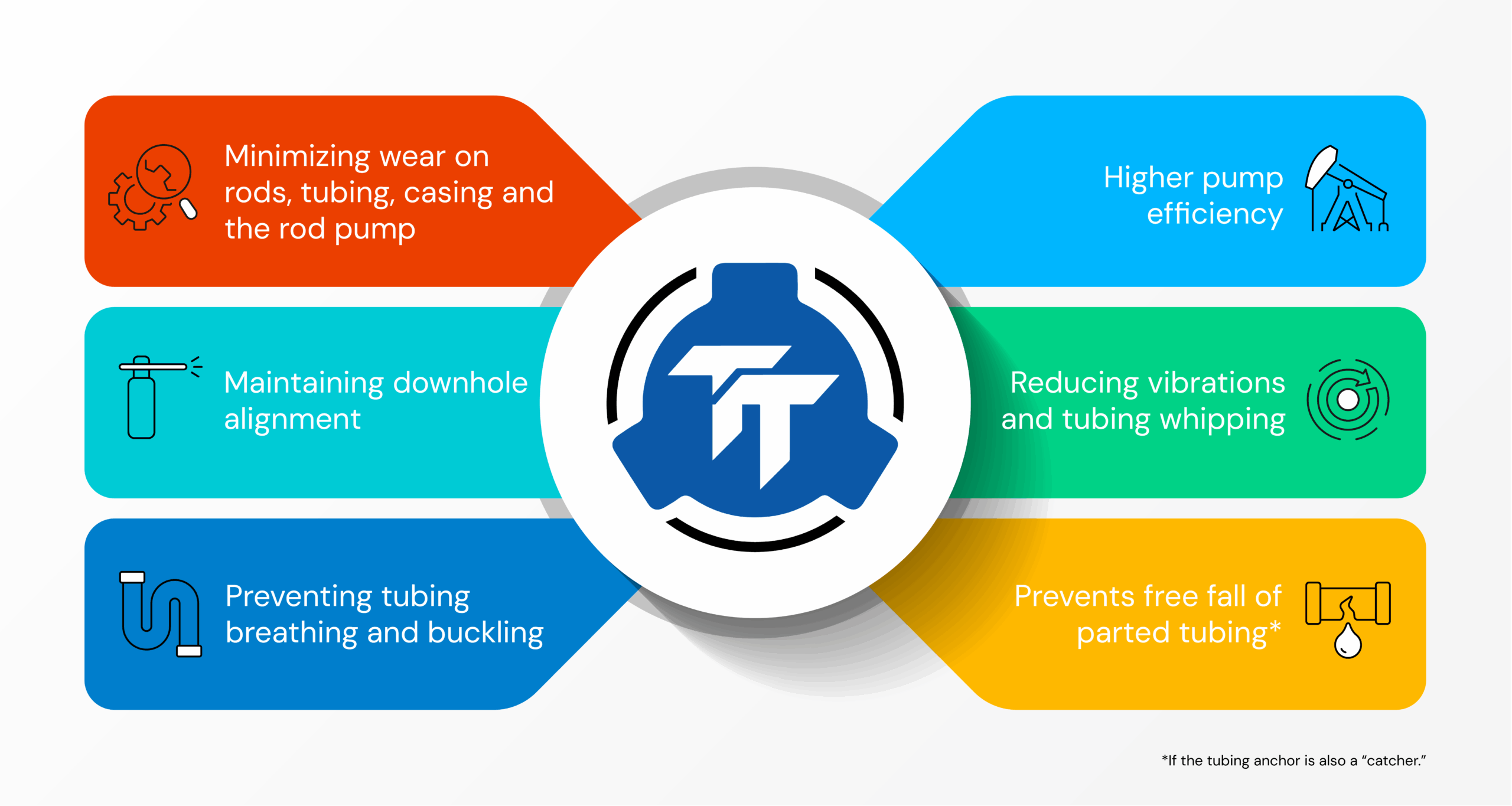

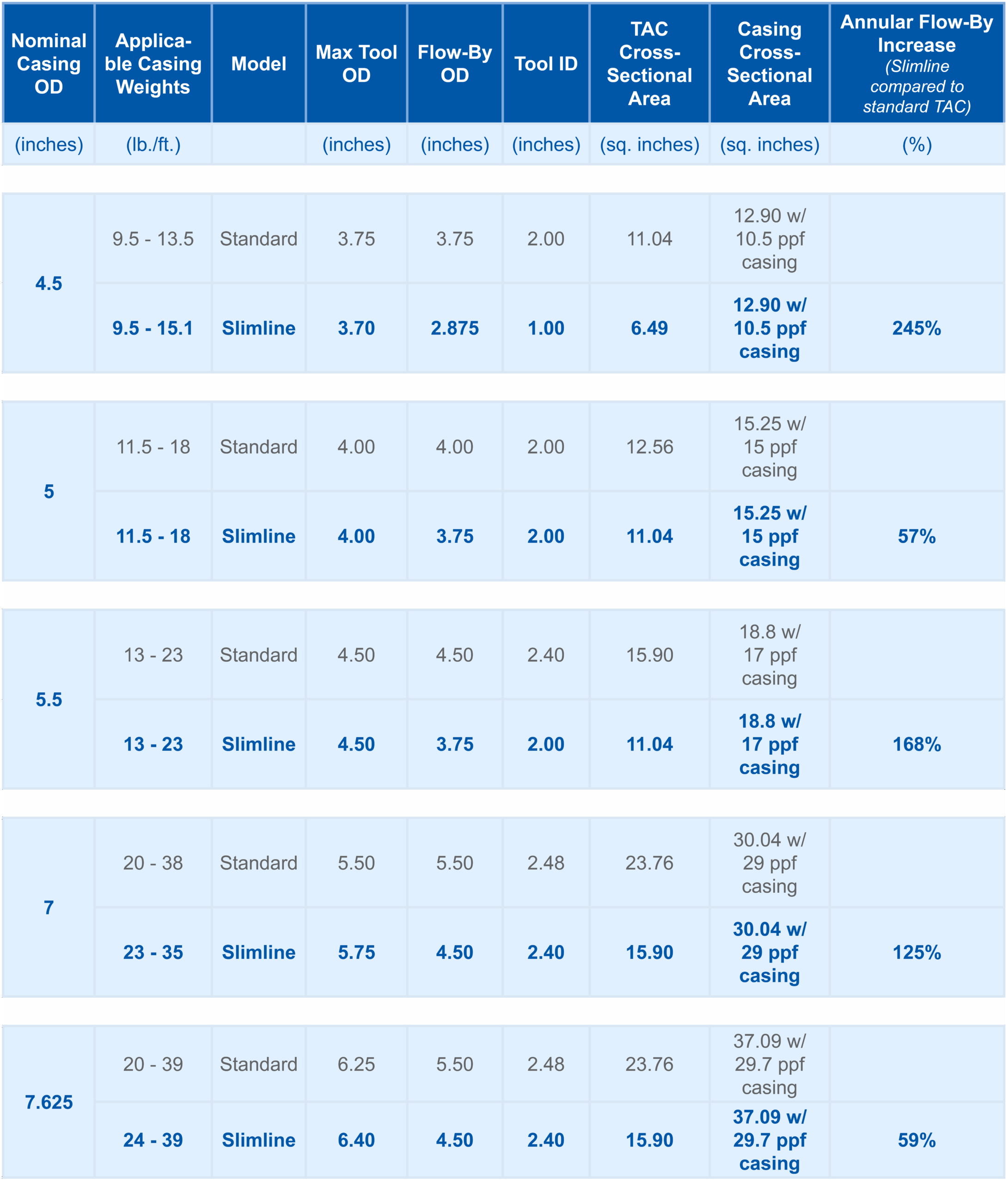

The Slimline® Full Bore™ Tubing Anchor Catcher gives engineers and operators more flexibility in where tubing anchors can be placed within a well when utilizing 2-7/8” tubing. The product’s design combines a full bore ID (2.4” on the 5.5” anchor) with the Slimline’s reduced OD. This combination allows the anchor to be placed above the seat nipple where 2-7/8” tubing and associated pump sizes are installed.

Slimline® Tubing Anchors

Thanks to its reduced overall diameter, Slimline® Tubing Anchor Catchers from TechTAC® offer up to 245% more flow-by area than standard B2 anchors. This unique design helps Slimline tubing anchors mitigate gas locking and sediment buildup.

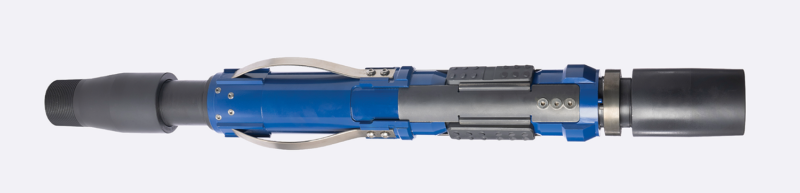

Slimline® QuickSet™ TAC

Slimline® QuickSet™ Tubing Anchor Catchers set in just 1-to-3 turns, as opposed to the traditional 6-to-8 turns, while still benefiting from the Slimline design. The reduced number of surface rotations required to set the anchor makes the Slimline® QuickSet™ TAC ideal for use in deep or deviated wells.

Standard B2 TAC

TechTAC® carries the most common sizes of the standard B2 tubing anchor catchers, which have been used in the industry for decades to improve efficiency and reduce downtime. By stabilizing the production string, a B2 TAC can minimize wear on rods, tubing, casing and the rod pump.

Quarter-Turn Tension Anchor

The right-hand set Quarter-Turn Tension Anchor is a compact, automatic-released anchor that can be set with minimal surface rotations and is easy to redress. The quarter-turn anchor eliminates the need for tubing swivel, and it can remain in tension, compression or neutral positions.

Unique Sizes & Applications

In addition to a large inventory of the most common sizes of tubing anchors, TechTAC® also offers unique sizes and applications of tubing anchor catchers, as well as custom tools, to meet the needs of less-common well designs.

Accessories

TechTAC® also offers additional products that complement the company’s high-quality tubing anchors. These accessories are supported by the same commitment to quality, dedicated service and timely delivery as our anchors.